Project Description

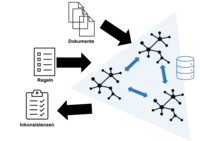

The planning of process plants requires parallel development across various disciplines such as process engineering, plant and mechanical engineering, and software development throughout multiple project phases. In particular, process control technology (PCT) involves the integration of numerous devices and heterogeneous documents, which can lead to inconsistencies. The goal of this project is to systematically identify such inconsistencies, assess their impact, and enable informed decisions regarding their resolution. A particular focus lies on the model-based representation of interdependencies between disciplines, in order to make change effects and the severity of inconsistencies more transparent. To this end, typical inconsistency scenarios will be analyzed, and an ontology will be developed for formal representation and populated with data extracted from real engineering documents. A corresponding software tool – the Inconsistency Detection and Tracking System (IEVS) – will be implemented to enable automated analysis and support especially small and medium-sized enterprises (SMEs) by reducing effort in decision-making. To ensure future viability in the context of Industry 4.0, the project also includes the development of a workflow for integration with Asset Administration Shells (AAS/VWS), as well as a concept for identifying inconsistencies between different AAS instances.

Project Partners

RWTH Aachen University, Lehrstuhl für Informations- und Automatisierungssysteme für die Prozess- und Werkstofftechnik (IAT)

BASF SE

Evonik Industries AG

KROHNE Messtechnik GmbH

LANXESS

LeiKon GmbH

Planets Software GmbH

Rösberg Engineering GmbH

SAMSON AG

Sedna Automation GmbH

TAUTOMATION.CONSULTING

Wacker Chemie